Bush Roller Chain

In a bushed chain, the two inner plates are held together by tubular bushings, which are like hollow rivets. High-quality bushed chains, like KMC’s e101 EPT and X101 are extremely durable.

Bush chain vs roller chain

The main difference is that bush chain does not have a roller. If the chain length is an even number of pitches the connection link may be used to connect two ends of the chain together. The chain power capacity is not reduced usually.

What are the different types of roller chains?

- ANSI Standard Roller Chain. ANSI Standard Multi-Strand Roller Chain. …

- Heavy Roller Chain.

- ANSI Standard A-Type Double Pitch Roller Chain. …

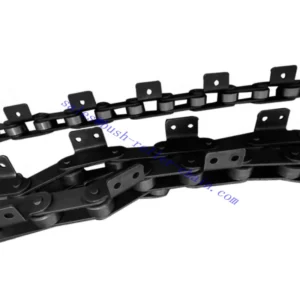

- Roller Chain With Attachments.

- Double Pitch Roller Chain With Attachments.

- ISO British (Metric) Standard Roller Chain. …

- Corrosion Resistant Roller Chain. …

- SL Series.

Top Destinations

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut.

Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum. Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

Our Products

A bush-roller-chain manufacturers, we will do our best to serve you. If you need customized products, or the products you need are not found on our website or need a product catalog, don’t worry; uploaded. You can email us directly, and we will reply within 24 hours!

-

03C ANSI 15 RS15-1 4.7625mm pitch miniature industrial transmission roller chain

-

10A-3 50-3 RS50 – 3 15.875mm Drive Bushing Roller Chain

-

10B-1 15.875mm Carbon Steel Single Drive Conveyor Roller Chain

-

50 Roller Chain 10 Feet with 1 Connecting Link

-

Professional Custom Bushing Roller Chain

-

Professional High Strength Bucket Elevator Conveyor Bushing Roller Chain

What is the common failure in roller chain?

Rust and corrosion are the biggest enemies for any machine that contains roller chains, and they are also highly common. You might find that a perfectly functioning and smooth roller chain might suddenly crack at the links, thus disrupting your operations.

When should I replace my roller chain?

Measure the roller chain for wear elongation. If the chain exceeds functional limits, or is greater than 1.5% (0.36 inch per one foot), then it’s time to replace the entire chain.

Why does my chain keep dropping?

What are the two types of roller chain?

Two types of roller chains are in common use namely (i) single strand, and (ii) multiple strands. In multiple strands, two or more chains are assembled side by side on common pins that maintain the alignment of the rollers in the several strands.

How do I know my roller chain size?

Most roller chain has the size stamped right into the side plates. You may see something like “40”, “C2080H” or “10B” stamped in, which the industry number that represents the chain size. Old chains will most likely need to be cleaned in order to see the size.